ME FIT Programs

We offer integral and technical solutions to help our customers tackle the unique challenges at each mining operation and to positively impact priority KPIs: tons per hour, safety management, availability and maintainability of equipment, risk prevention, among others.

We design solutions to help our customers achieve their goals by combining crusher wear parts with technology tools, advice, training and monitoring — all of which allow us to create value in our customers’ processes.

Products and services

Test conducted at a mine shows no detachment of inserts or fractures in the cast elements.

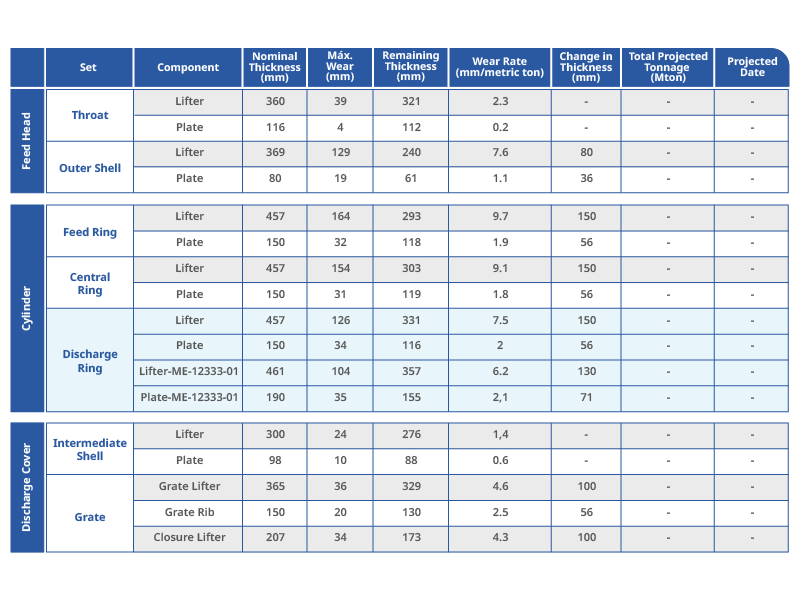

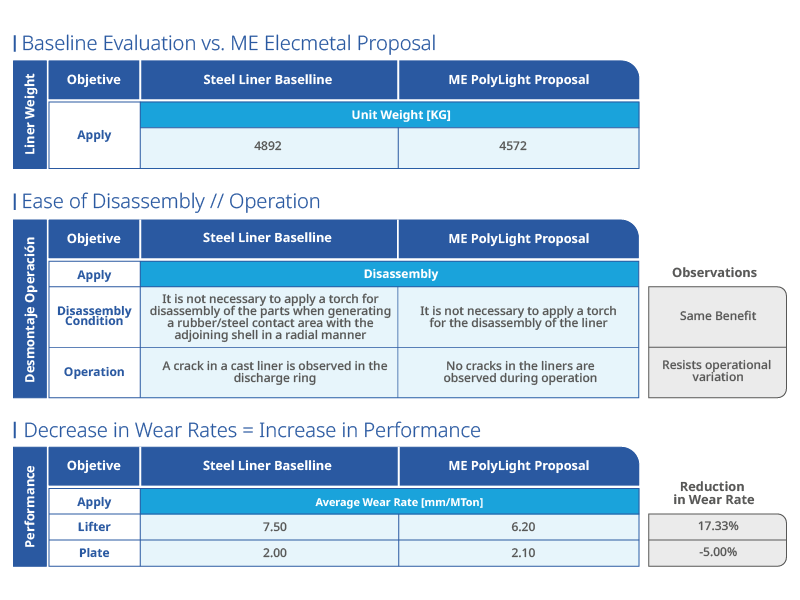

ME Elecmetal identified a customer’s need to stabilize periods of operational instability at a concentrator plant with a SAG grinding line featuring a 40×29 foot SAG mill and two 27×49-foot ball mills. In collaboration with the plant’s personnel, the ME Elecmetal team conducted a validation test of the ME PolyLight design and configuration liners.

During the test, the SAG mill was equipped with 30 cast SMX design lifters in the discharge ring. While the SMX liners met the client’s durability and performance expectations, ME Elecmetal sought to address the challenge of absorbing drastic operational changes.

ME Elecmetal proposed the ME PolyLight design concept, which includes a cast lifter and an ME PolyFIT™ plate.

In response to unstable operations and liner sensitivity, we developed a product design to absorb constant operational changes, aiming to fully optimize the copper production process.

To address these challenges, the ME Elecmetal team replaced the SMX design with the ME PolyLight solution. This design features a plate with rolled steel inserts and a cast lifter section, specifically engineered to absorb operational deviations in the SAG mill and withstand high-impact conditions.

Notes:

Actual Results for the Client:

ME FIT Programs

Products and services

Mining 4.0

Your message will be reviewed by our area managers and they will contact you shortly

Keep up to date with the latest news from ME Elecmetal.

document.getElementById( "ak_js_2" ).setAttribute( "value", ( new Date() ).getTime() );