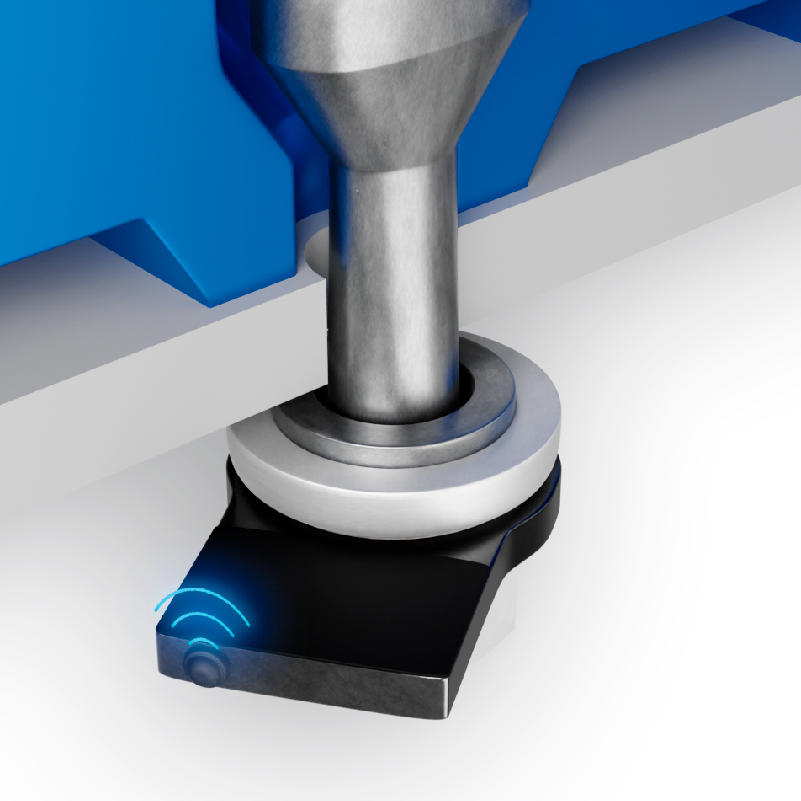

The bolt tension monitoring sensor offers ongoing measurements of bolt tightening, actively monitored by our analysts. It operates within a wireless network, communicating with a cabinet located on the ground that enables data to be displayed on a monitoring platform for easy access and analysis.

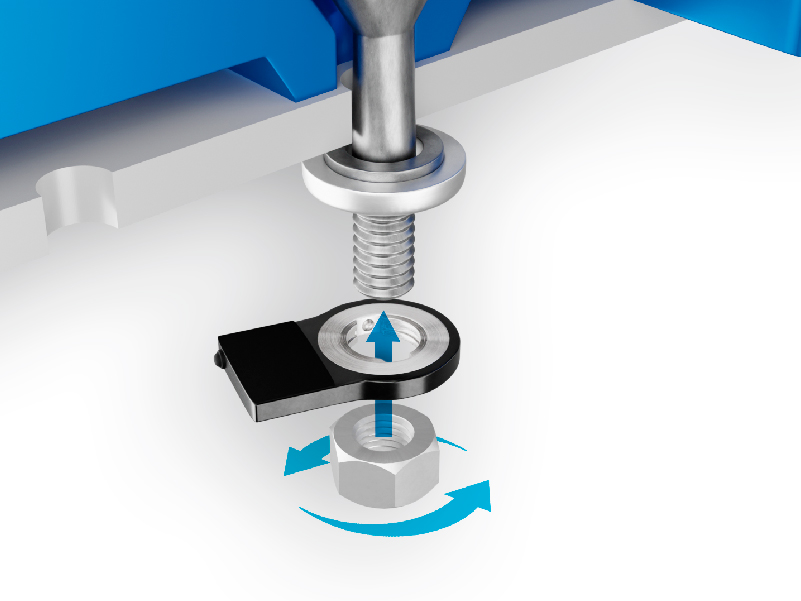

Each sensor corresponds to a device integrated into the assembly of the fastening elements. This installation task is executed swiftly and safely. It involves placing the sensor between the cup collar and the nut, effectively measuring the load, which correlates with the instantaneous tension experienced by the bolt.

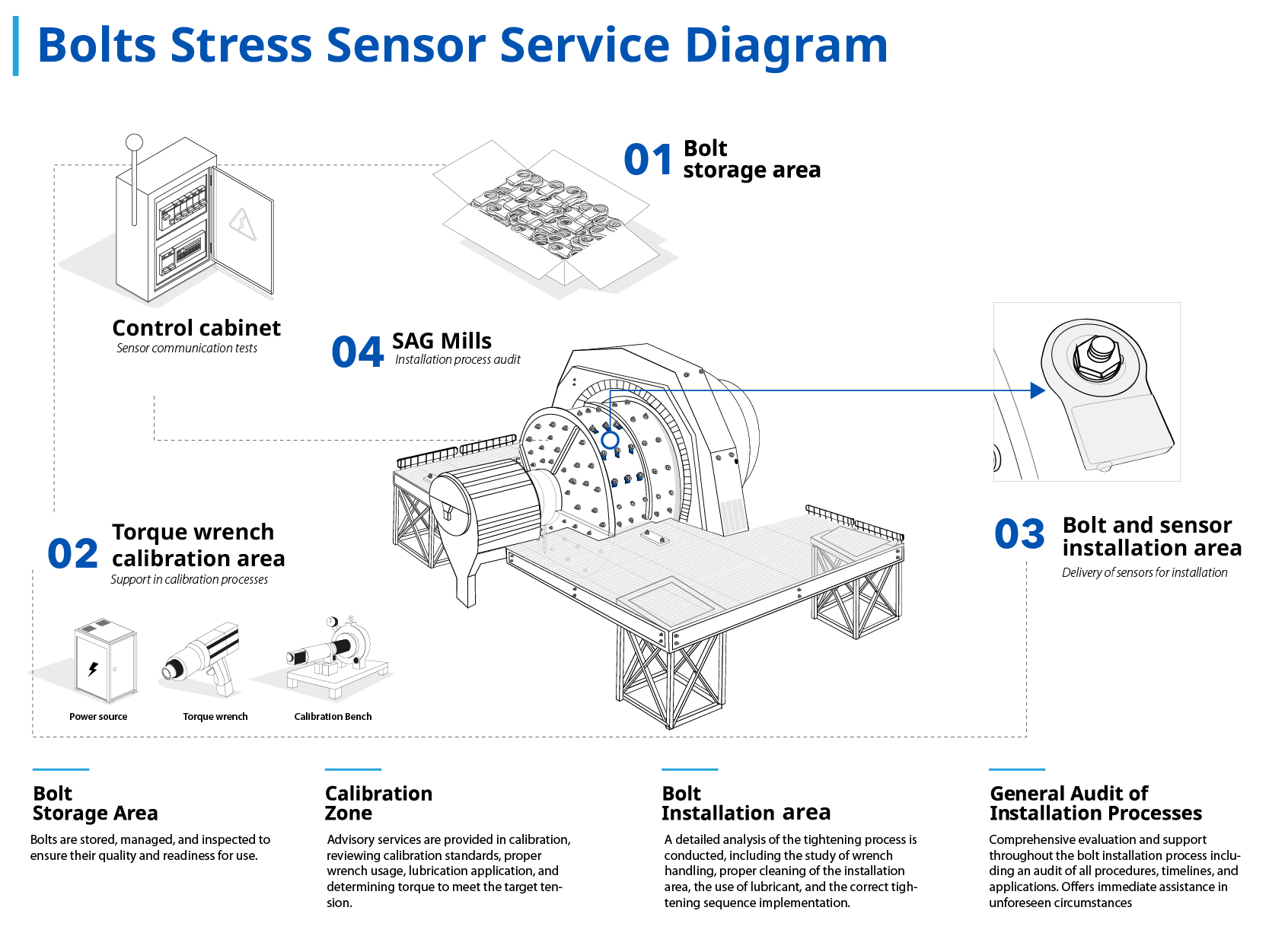

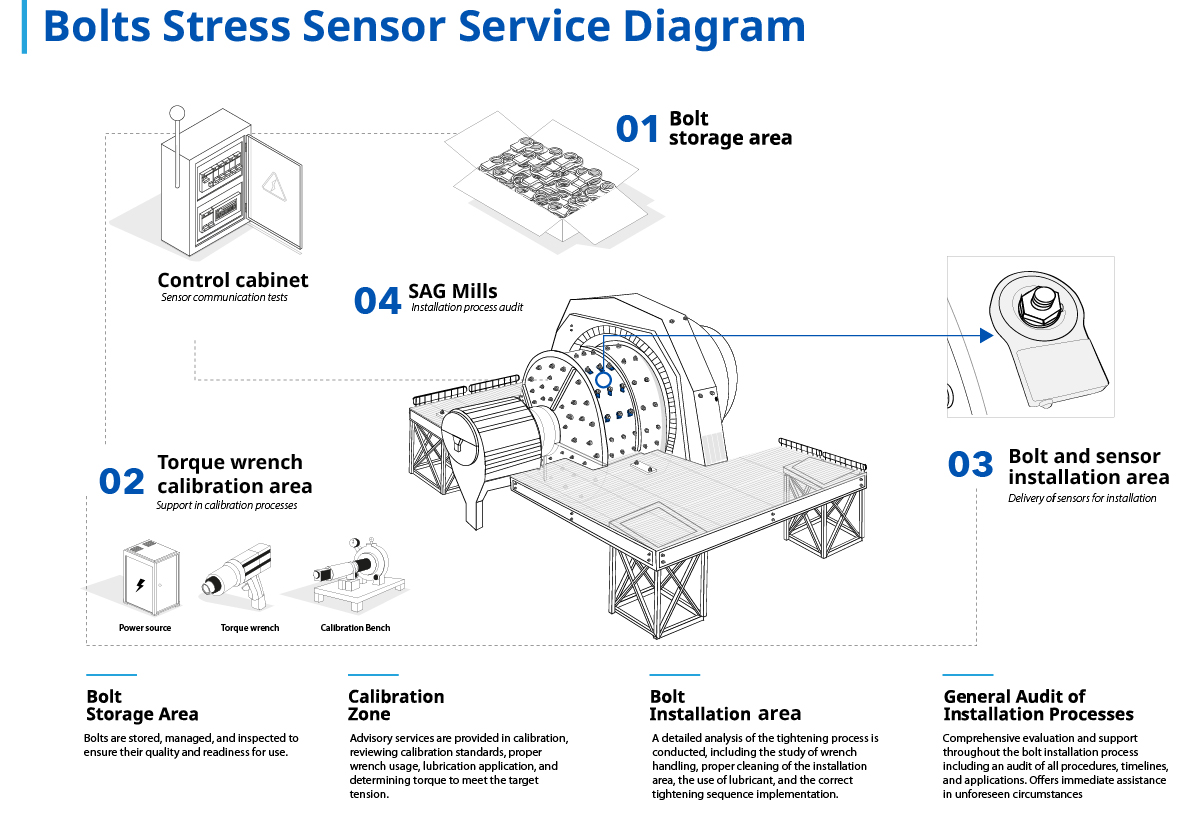

The system’s information flow begins with acquiring load data from each sensor, which is wirelessly transmitted to the control cabinet located near the mills. The cabinet then forwards this data to a server for analysis and standardization. Eventually, this dataset is uploaded onto the web platform, enabling authorized users to access and review the tension data.