PROGRESS IN SOUTH AMERICA

In Chile, the audit processes integrate Quality, Environment, and Health and Safety, while Energy Efficiency is managed autonomously. The audit involves a one-week review conducted by four to five auditors in the field. During this period, interviews are held with line management, operators, and contractors across all relevant areas to ensure the management system meets the required standards for recertification.

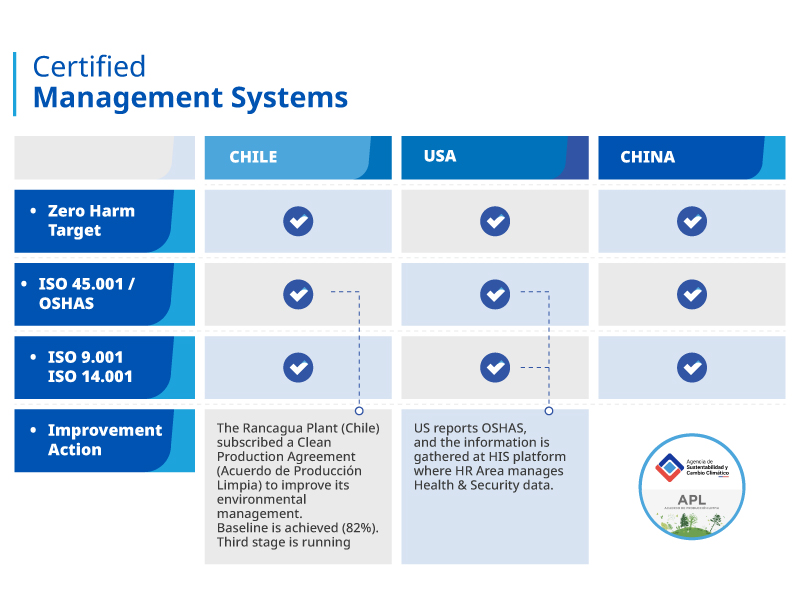

The Rancagua plant has been certified under the Occupational Health and Safety Management System since 2018, initially with OHSAS 18001. As of 2021, the certification has been updated to ISO 45001, which replaces the previous standard.

The certification and recertification process occurs every three years. The certifying company, in this case LQRA, visits the Rancagua plant to conduct a comprehensive audit of the entire process. They assess compliance with standard requirements, and if the plant meets these requirements, the certification is renewed for another period. The scope of this certification covers four key processes:

- Engineering and development services

- Manufacturing, reconditioning and machining of components for the mining and industrial sectors.

- Commercialization of parts and equipment for large mining operations.

- Development of digital and analog services methodologies to provide integral solutions to customers.

Additionally, both follow-up and internal audits are conducted to ensure ongoing compliance with the company’s objectives. These objectives are centered around zero-harm management, focusing on cultivating a strong safety culture, enhancing leadership, and managing exposure risks, while adhering to ME Elecmetal’s health and safety policies.