ME FIT Programs

We offer integral and technical solutions to help our customers tackle the unique challenges at each mining operation and to positively impact priority KPIs: tons per hour, safety management, availability and maintainability of equipment, risk prevention, among others.

We design solutions to help our customers achieve their goals by combining crusher wear parts with technology tools, advice, training and monitoring — all of which allow us to create value in our customers’ processes.

Products and services

ME Elecmetal delivers a reliable fastening solution designed to reduce operational deviations, strengthen asset reliability, and optimize KPIs for safety, availability, and productivity.

Our client, a major copper producer, identified the need for a comprehensive consulting proposal to strengthen the bolting and fastening elements of all SAG mill liners as part of its upcoming expansion project. The operation features a SAG–ball mill grinding circuit designed for large-scale copper sulfide extraction:

SAG Mill (40×29 ft) – Equipped with a lifter/plate cylinder configuration in a three-ring layout (Feed / Central / Discharge).

Ball Mill (27×49 ft) – Providing critical secondary grinding capacity to maximize metal recovery.

By targeting fastening reliability at the core of these mills, the client sought to strengthen safety, availability, and long-term performance as the operation scales up production.

This challenge set the stage for the Smart Bolting System (SBS)—ME Elecmetal’s market-leading solution engineered to eliminate fastening deviations and ensure consistent, verifiable performance. Unlike any other option in the market, SBS uniquely combines innovative fastening technology with premium-quality products, enhanced by tailored training and consulting to meet each customer’s specific needs.

ME Elecmetal delivered a comprehensive fastening proposal for SAG mill liners, fully aligned with the parameters of the Smart Bolting System (SBS). The solution was structured into three stages to ensure both operational excellence and long-term reliability:

Hands-on training for the client’s maintenance team on fastening elements.

Definition of installation tensions and standardized procedures according to liner design.

Calibration of torque wrenches to guarantee accuracy and consistency.

On-site technical support during maintenance activities.

Verification that fastening procedures were applied correctly.

Deployment of a secure web platform for real-time tension monitoring.

Delivery of biweekly reports to track fastening conditions.

Definition of a re-torque or re-tightening plan for sustained fastening integrity.

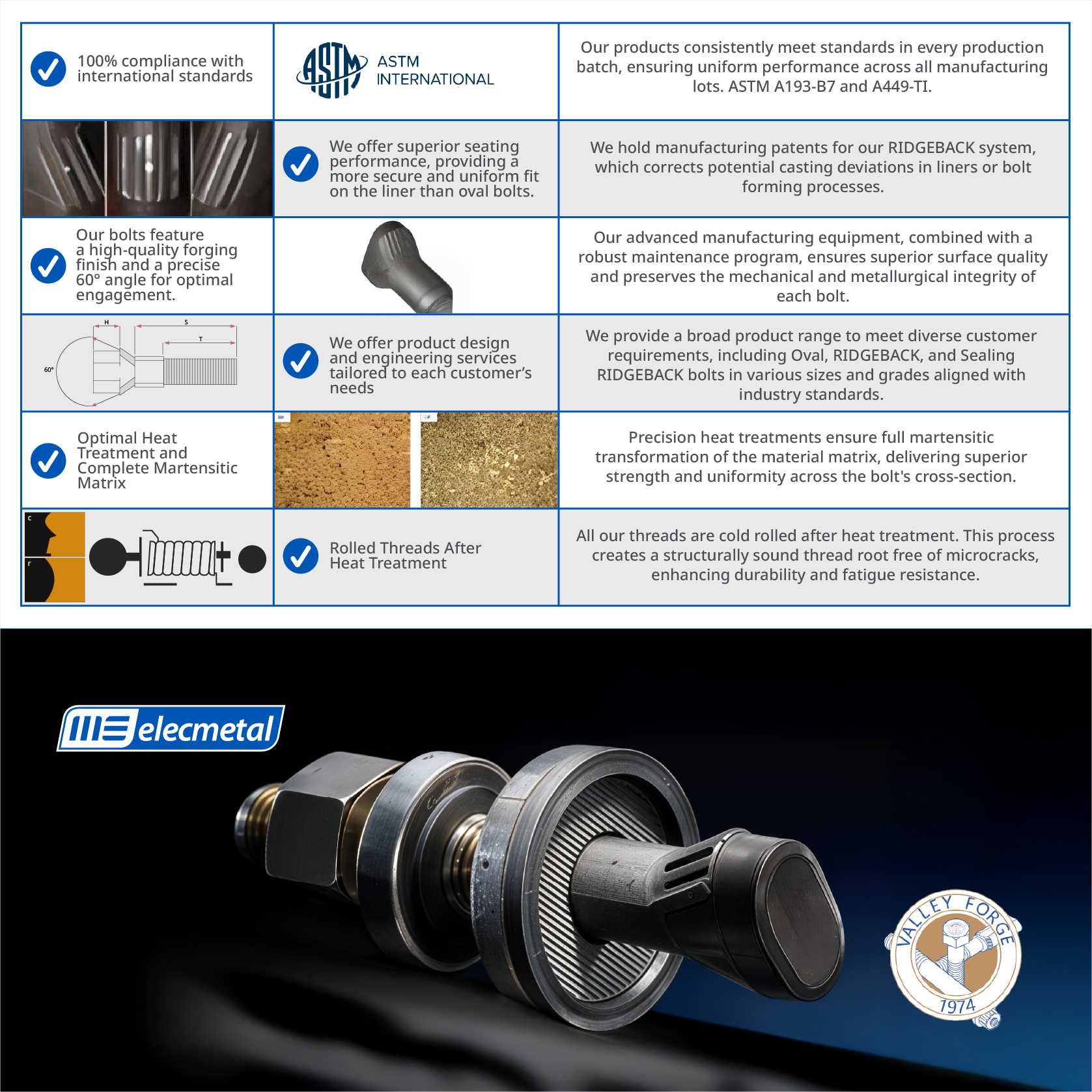

To complement the service framework, ME Elecmetal conducted a study on the liners to determine the exact installation tension required for optimal operation. The solution incorporated Ridgeback – ValleyForge bolts, which provide a superior fit and secure seating within liner bores, further enhancing fastening reliability.

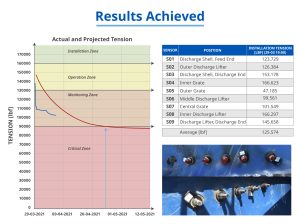

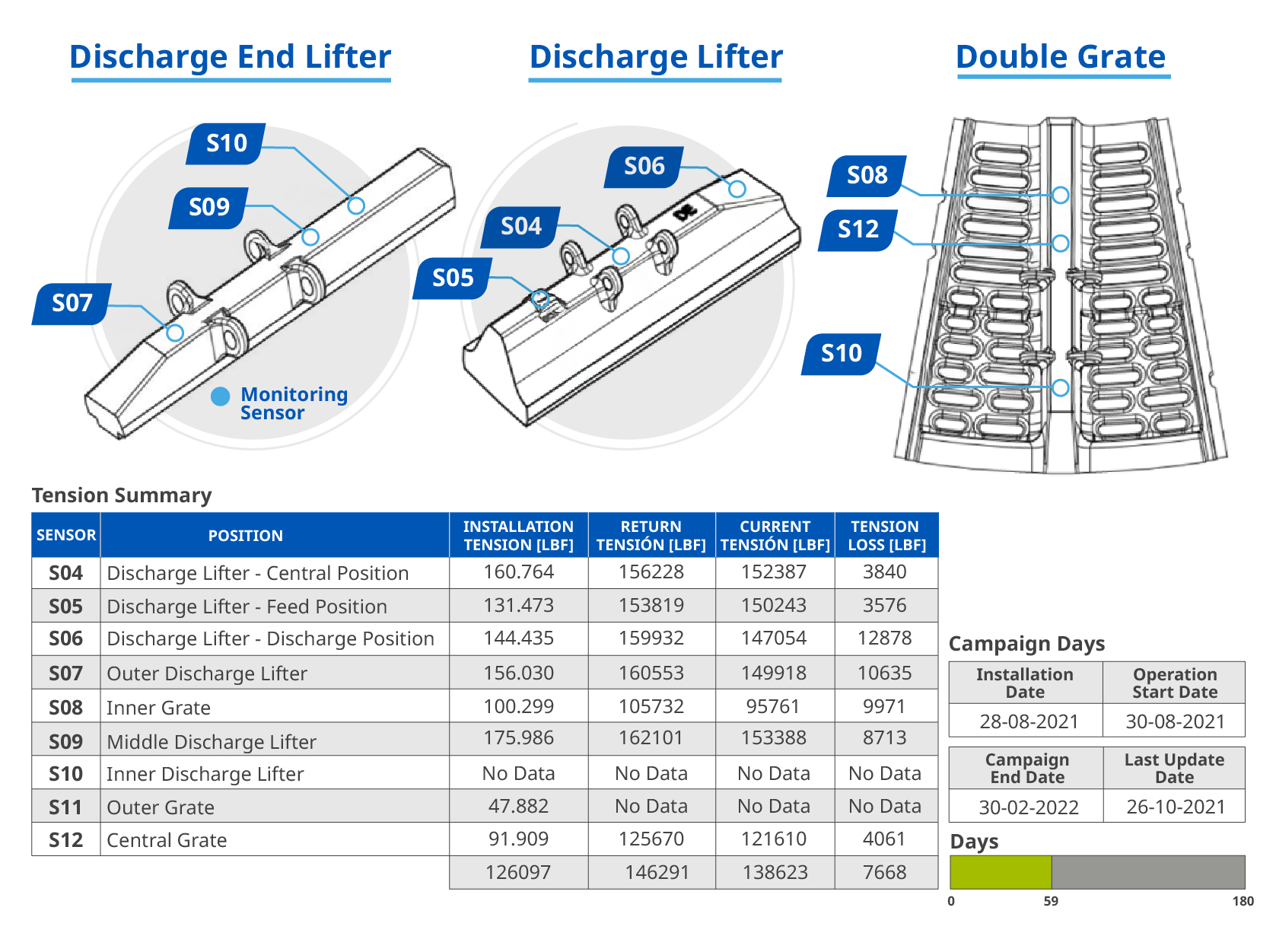

Additionally, tension sensors were installed to continuously monitor fastening performance throughout the campaign, verifying that the recommended installation tension of 170,000 lbf was consistently achieved and maintained.

The proposed solution integrates specialized training, precision torque wrench calibration, the implementation of online tension sensors, and the supply of high-performance fastening elements—all designed to ensure safer installations and greater long-term reliability.

ME Elecmetal delivered measurable improvements in fastening performance and asset reliability. By recording and monitoring installation tensions, the system enabled early detection of deviations during the installation process. This proactive approach allowed timely re-torque adjustments, preventing potential failures or breakages and ensuring consistent fastening integrity throughout the campaign.

ME FIT Programs

Products and services

Mining 4.0

Your message will be reviewed by our area managers and they will contact you shortly

Keep up to date with the latest news from ME Elecmetal.

document.getElementById( "ak_js_2" ).setAttribute( "value", ( new Date() ).getTime() );