ME FIT Programs

We offer integral and technical solutions to help our customers tackle the unique challenges at each mining operation and to positively impact priority KPIs: tons per hour, safety management, availability and maintainability of equipment, risk prevention, among others.

We design solutions to help our customers achieve their goals by combining crusher wear parts with technology tools, advice, training and monitoring — all of which allow us to create value in our customers’ processes.

Products and services

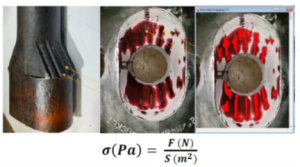

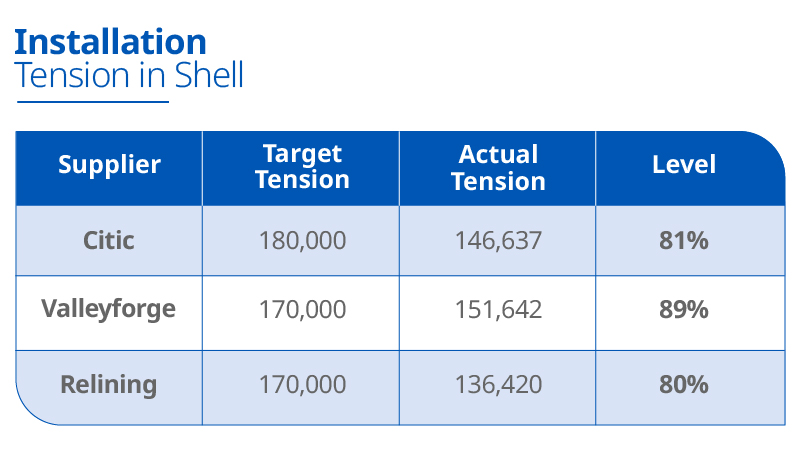

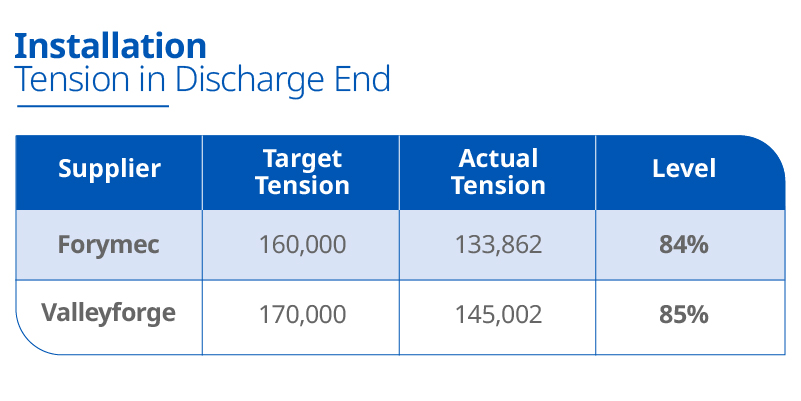

Compared to other suppliers, installation tension levels, measured with calibrated installation tools at 170,000 lbf, demonstrated superior performance. The shell reached 89% of the target tension, while the discharge end achieved 85%.

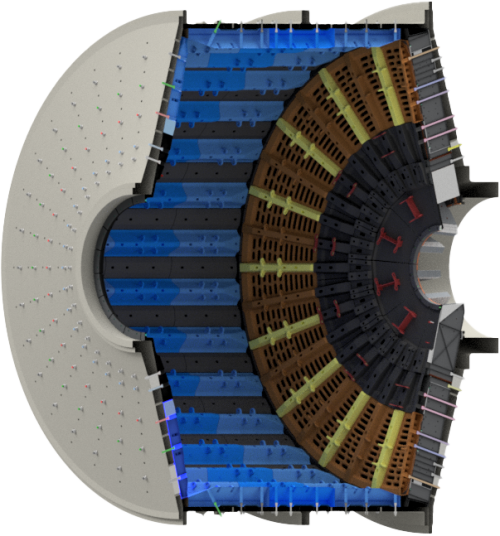

Following a shutdown in September 2022, ME Elecmetal conducted a thorough assessment and identified areas for improvement in the calibration processes of installation tools, torque application, and retorquing procedures at one of its client’s operations. The primary objective was to mitigate occurrences of bolt loosening and failures experienced during the February 2022 campaign, particularly affecting the SAG mill’s discharge end and shell. This included the total fracture of 10 bolts, leading to the detachment of two grates and subsequent economic losses due to unscheduled downtime, impacting the mill’s availability.

ME Elecmetal was dedicated to enhancing installation procedures and identified an opportunity to develop a comprehensive solution aimed at ensuring the reliability of liner fasteners on the shell and discharge end of SAG mills. This initiative was based on insights collected during the major shutdown in September 2022, when the online monitoring system was implemented.

The following recommendations were considered:

For monitoring bolt tension, the installation of 73 sensors was proposed, with 38 allocated to SAG Mill 1 and 35 to SAG Mill 2.

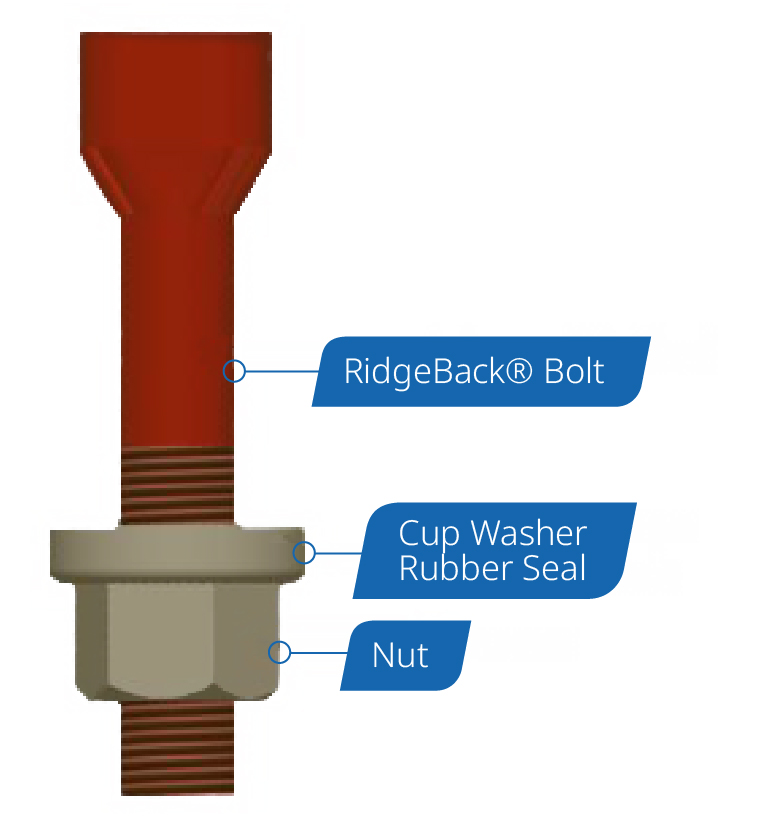

The implementation and validation of Valley Forge bolts for SAG Mill 1 were carried out in both the shell and discharge end.

Valley Forge Ridgeback Bolt

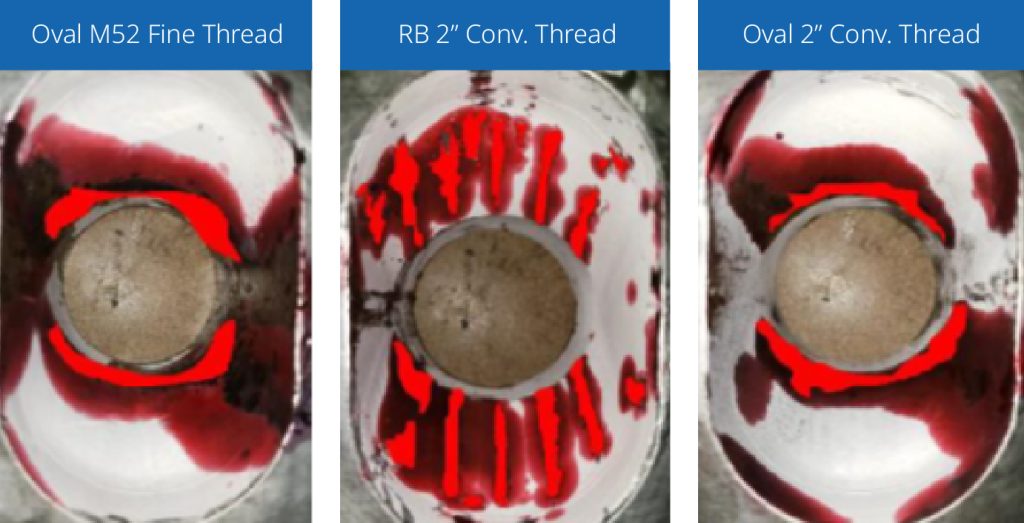

Comparison between an oval bolt and a Valley Forge Ridgeback bolt

Valley Forge bolt fastening kit

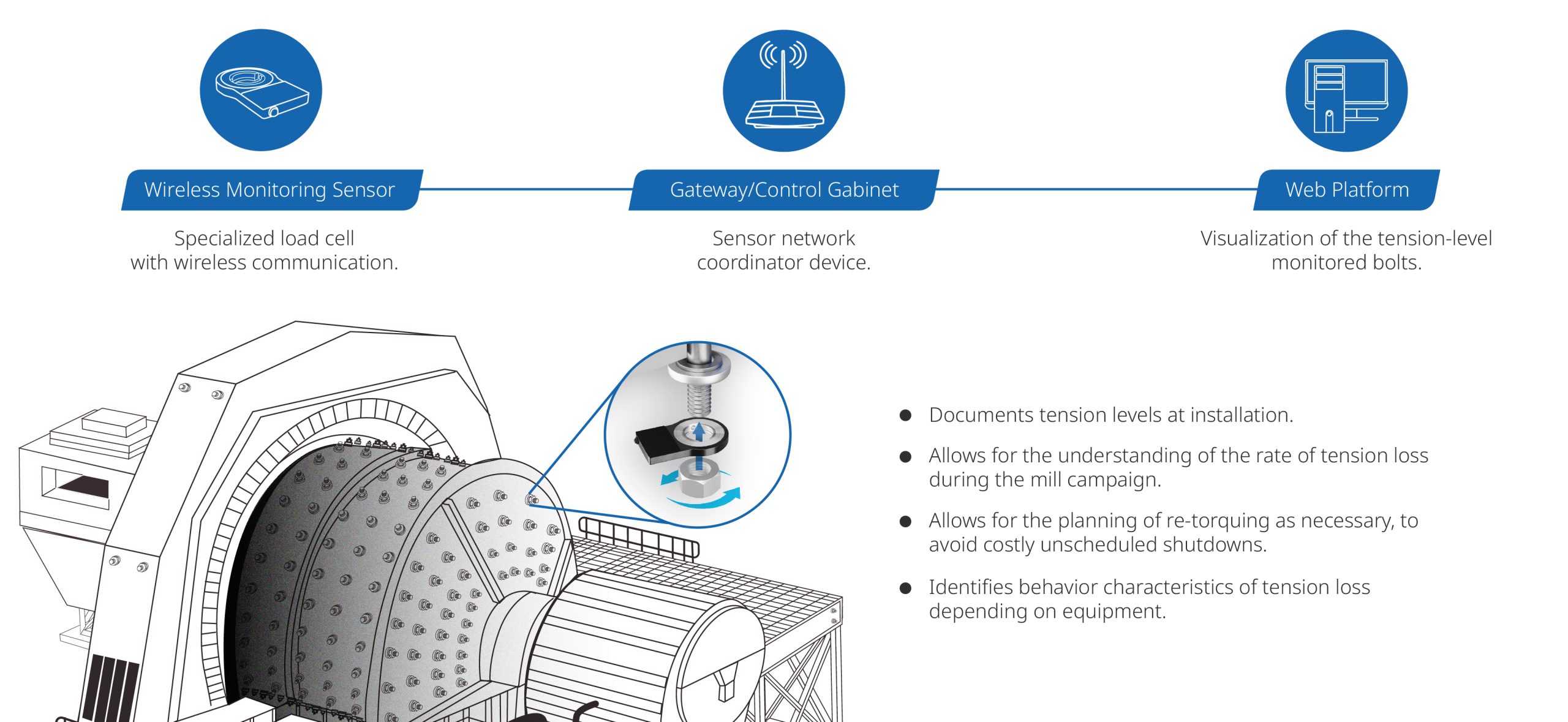

Tracking and monitoring were implemented with the bolt tension monitoring system:

Operation of the online monitoring system

The implementation and validation process improved the bolt fastening system installation procedures emphasizing the selection of appropriate tools, ensuring correct assembly from each bolt supplier, implementing proper storage and protection measures for bolt and nut threads, optimizing bolt lubrication, and establishing a standardized bolt torque sequence.

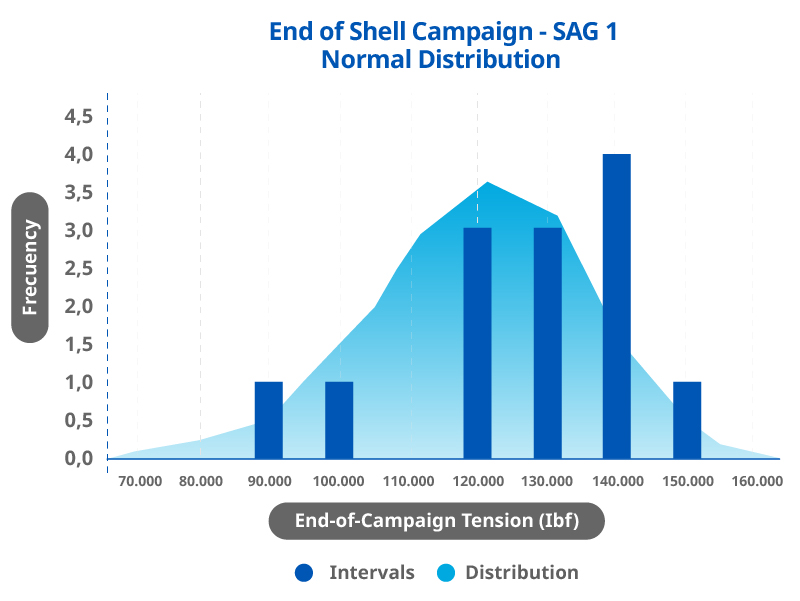

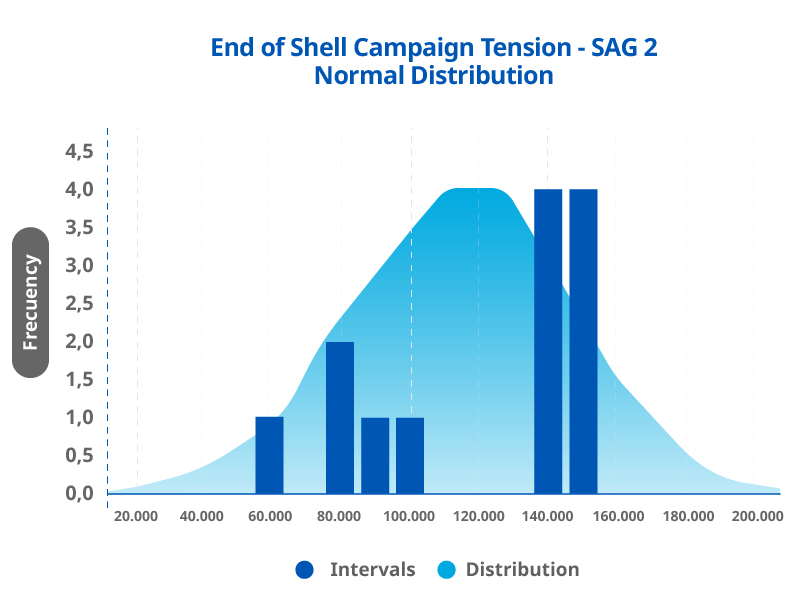

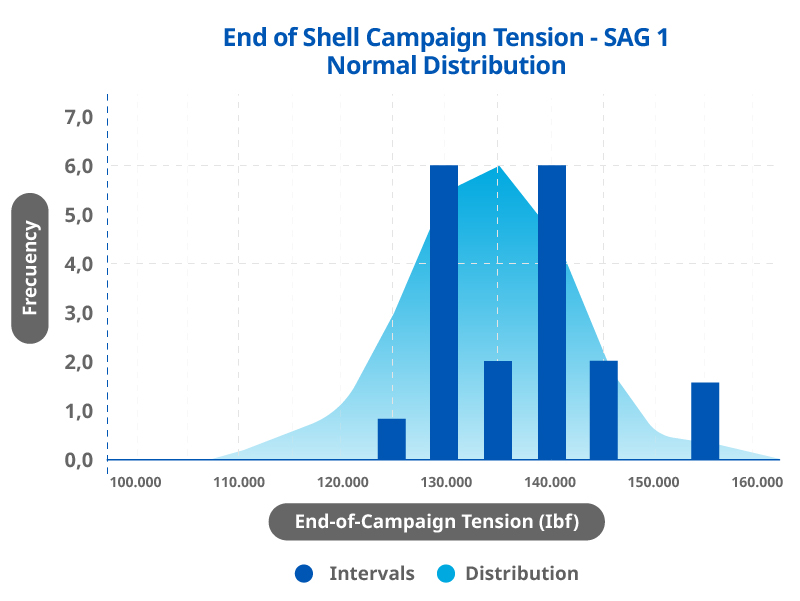

End-of-Campaign Shell Tension

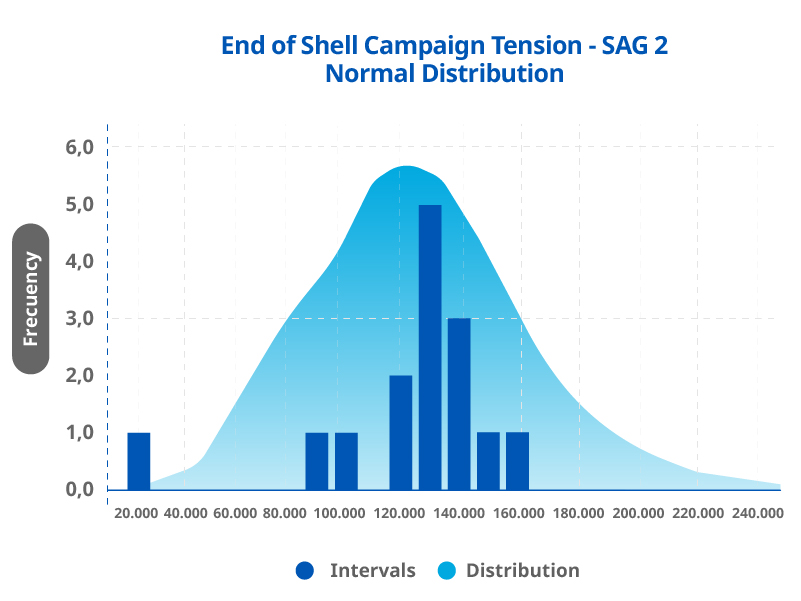

End-of-Campaign Tension Discharge End

ME FIT Programs

Products and services

Mining 4.0

Your message will be reviewed by our area managers and they will contact you shortly

Keep up to date with the latest news from ME Elecmetal.

document.getElementById( "ak_js_2" ).setAttribute( "value", ( new Date() ).getTime() );