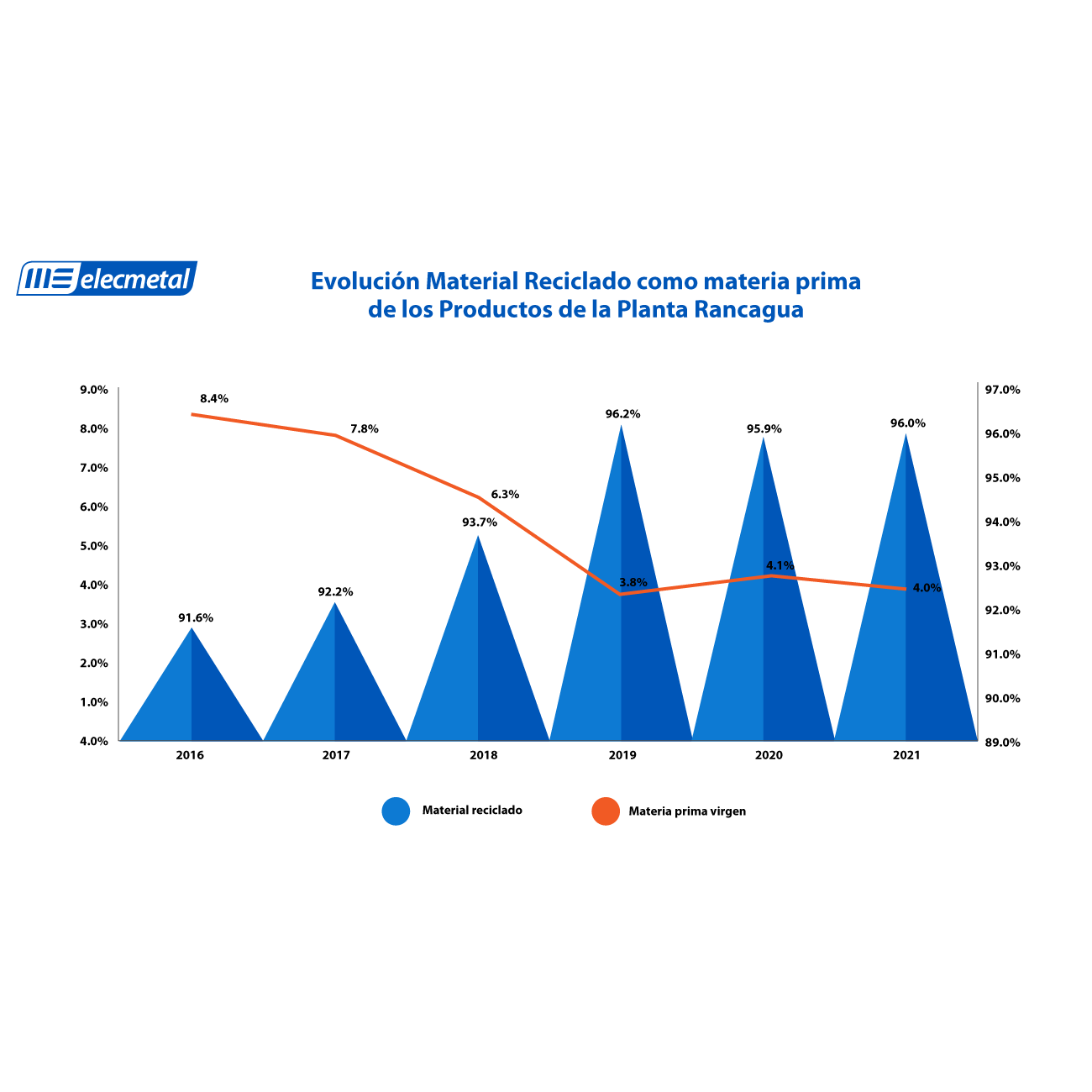

Since 2016, the operations area, together with other support teams, has sought to increase the circularity of the products we develop. To this end, we have progressively integrated recycled raw materials in the different products developed locally, as is the case of steel liners.

We began by identifying the composition of these products, once used by mining customers. The result of the research was to understand that once these components were implemented in the mining processes, they still had 95% of material that could be reused.

Therefore, the supply area monitors the purchases made by the customers, and then buys and recirculates the scrap and reconverts it into a new liner.